Plastic Injection Molding Services

MotMould – Your Trusted Partner for Plastic Injection Molding Services

MotMould is a manufacturing-focused partner delivering advanced plastic injection molding services for OEMs, industrial manufacturers, and product-driven companies. We support injection molding projects across the complete product and tooling lifecycle — from early-stage part design and mold engineering to serial production, tooling maintenance, and long-term manufacturing support.

Our integrated capabilities combine mold design, tooling production, injection molding, and manufacturing-oriented engineering to deliver high-quality plastic components optimized for performance, consistency, and scalable industrial production.

Discuss your injection molding project with our team and evaluate how MotMould can support your manufacturing objectives.

Comprehensive Injection Molding Capabilities

We provide a complete portfolio of plastic injection molding services designed to support product development, pilot production, and high-volume serial manufacturing. Our approach ensures technical alignment between part design, tooling, material selection, and production processes, minimizing risks and ensuring stable, repeatable output.

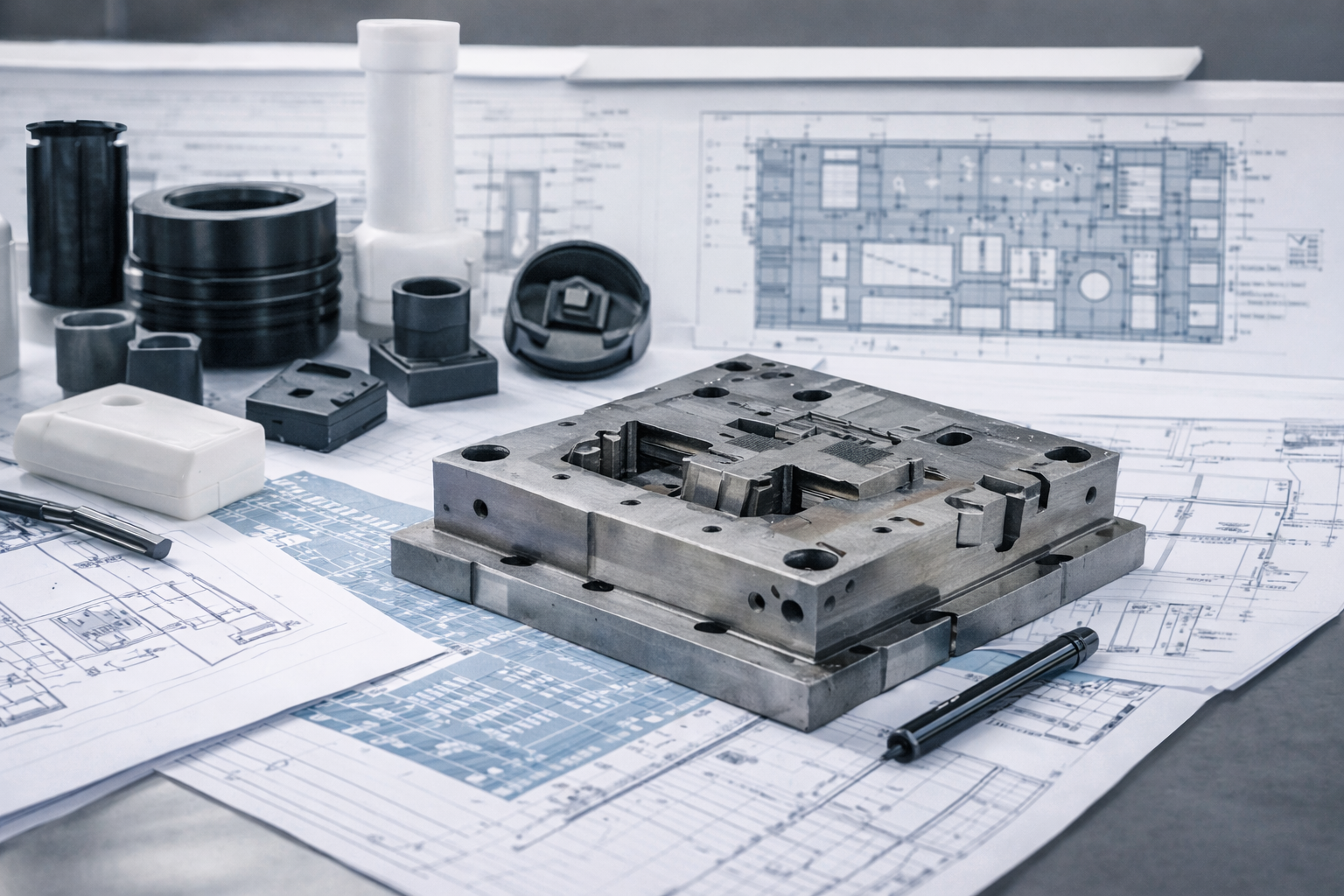

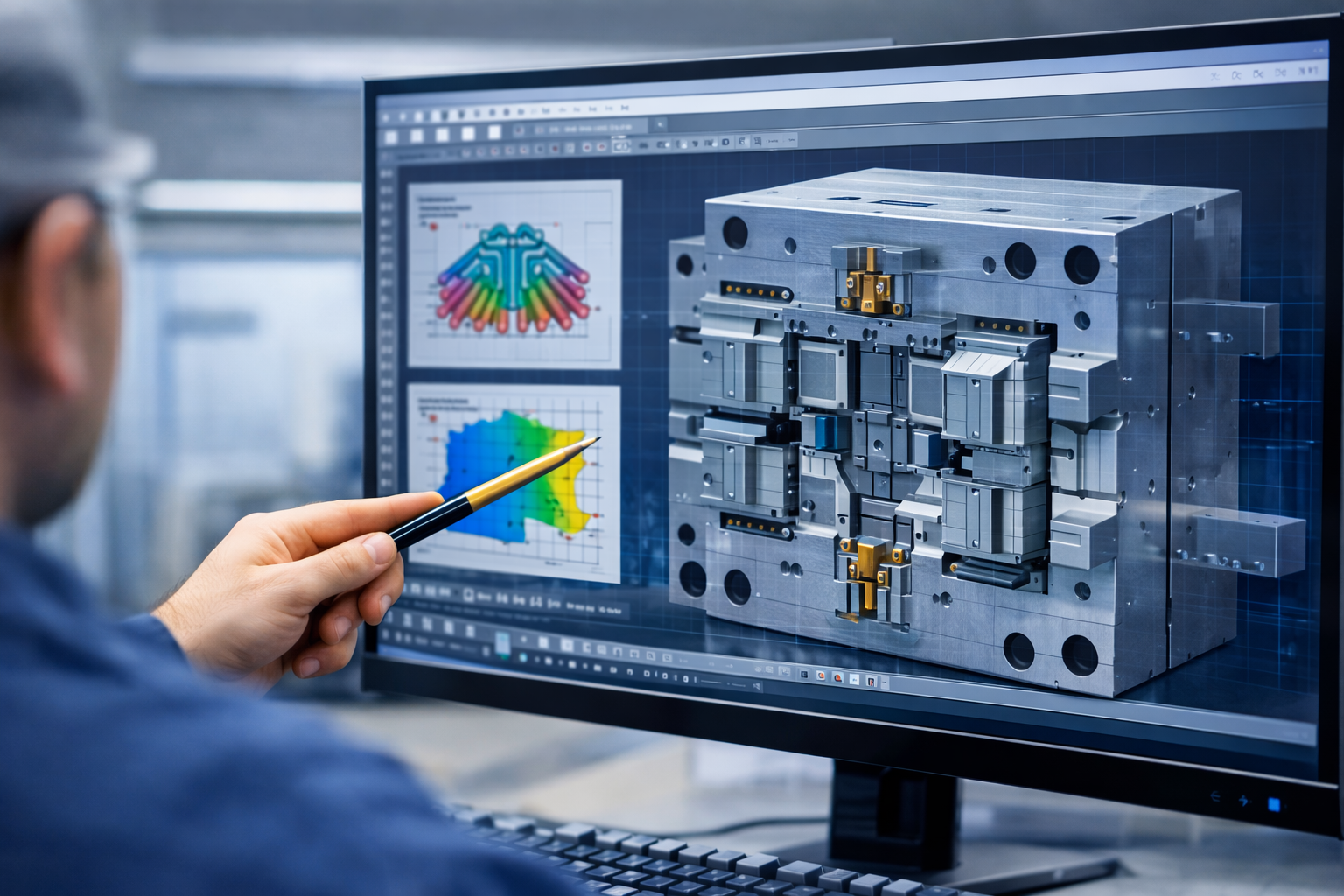

Mold Design & Engineering

We deliver professional mold design and engineering services focused on tooling performance, manufacturability, and long-term production reliability. Our engineering process includes part geometry evaluation, material flow analysis, gating and runner system design, cooling optimization, and ejection system configuration.

Each mold is engineered to achieve dimensional accuracy, stable cycle times, and consistent part quality under real serial production conditions.

Planning a new injection mold? Let’s review your part and tooling requirements together.

Mold Manufacturing & Tooling Production

Our mold manufacturing capabilities cover the production of high-quality injection molds for industrial applications. We produce tooling designed for durability, repeatability, and ease of maintenance, supporting prototype molding, low-volume production, and high-volume serial manufacturing programs.

All tooling is manufactured and validated to meet strict quality standards and verified for performance in real production environments.

OEM & ODM Manufacturing

MotMould supports OEM and ODM manufacturing programs by transforming customer concepts into fully manufactured plastic components and products. Our production infrastructure and experienced manufacturing team enable efficient scaling from pilot production to mass manufacturing.

We work closely with customers to ensure technical compliance, consistent quality, and reliable delivery aligned with production schedules and cost targets.

Looking for a reliable OEM or ODM injection molding partner? Contact our team to discuss your project.

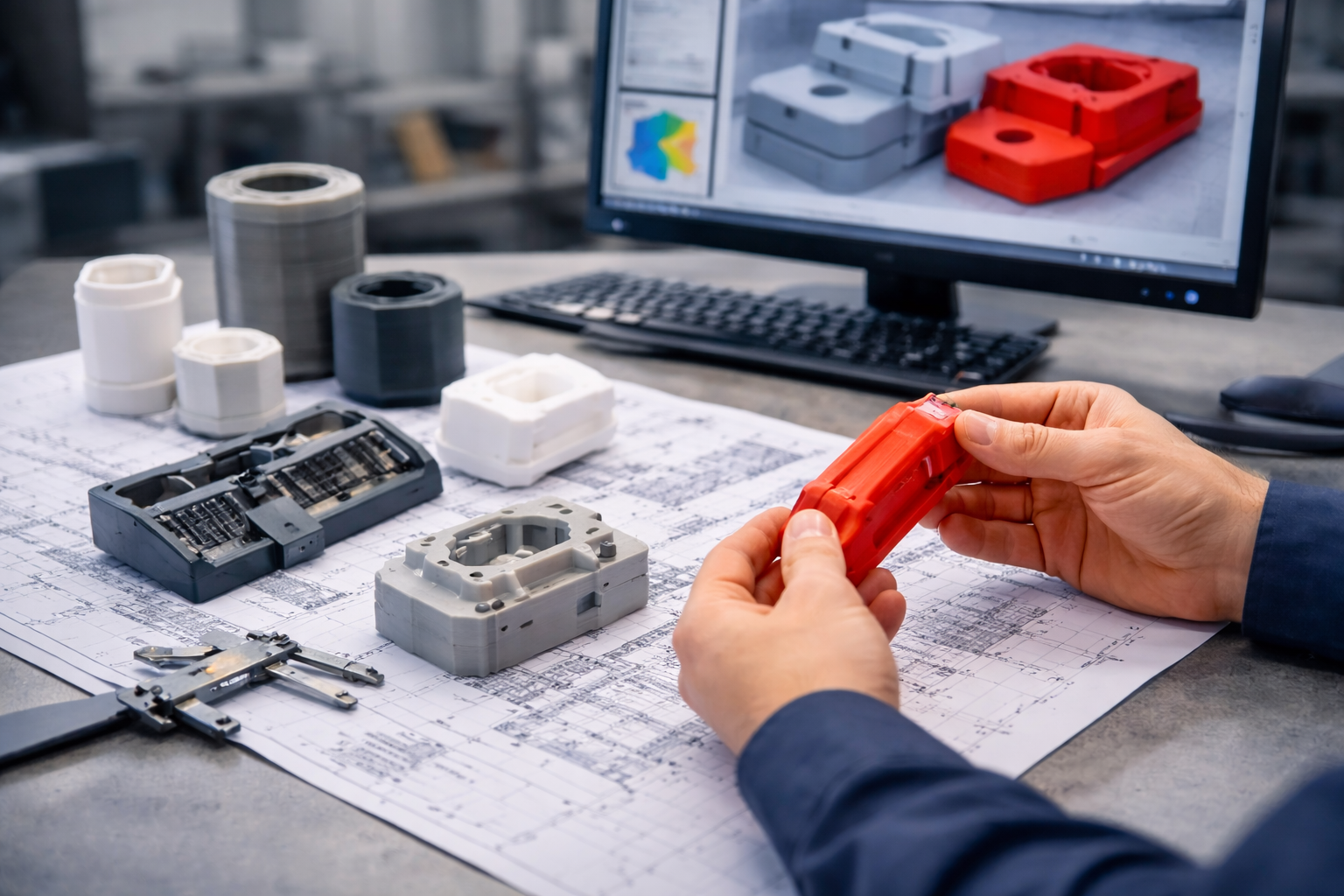

Plastic Product Design & Development Support

Our plastic product design and development support services help optimize product concepts for injection molding and industrial manufacturing. We focus on design for manufacturability, functional performance, and cost efficiency while maintaining required aesthetic and dimensional standards.

This collaborative approach reduces development risks, shortens time-to-market, and improves overall product robustness.

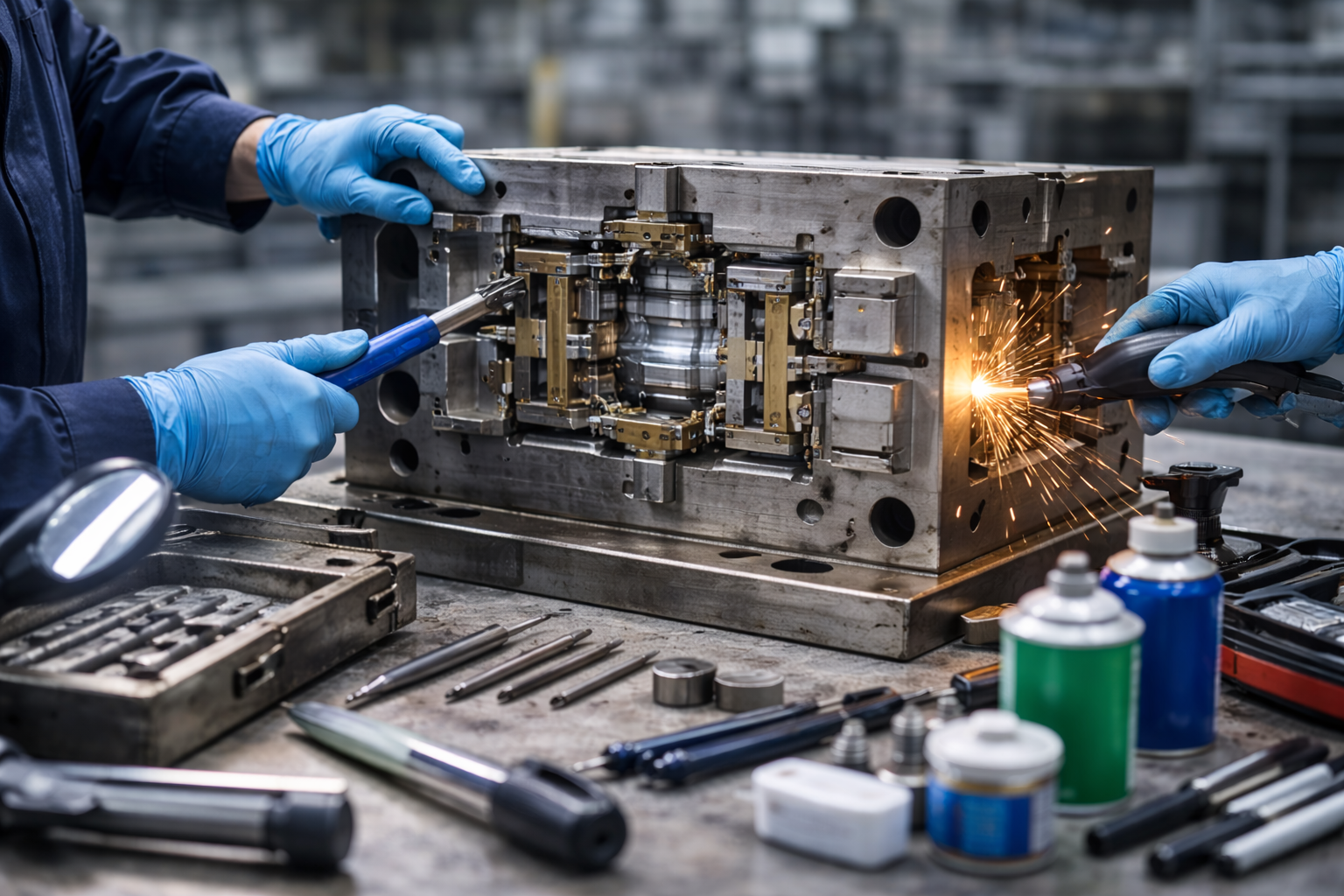

Injection Mold Repair & Maintenance Services

We provide comprehensive injection mold repair and maintenance services to extend tooling lifespan and maintain stable production performance. Our services include tooling condition assessment, corrective repairs, preventive maintenance, and process-related optimization.

Structured maintenance programs help reduce unplanned downtime, protect part quality, and ensure consistent output throughout long-term manufacturing programs.

Need mold maintenance or tooling repair support? Talk to our injection molding specialists.

Quality-Driven Manufacturing Approach

Quality is embedded across all stages of our injection molding operations. We apply controlled production processes, documented procedures, and dimensional inspection practices to ensure molded components meet defined specifications and customer requirements.

Our quality-driven approach ensures dimensional consistency, repeatable cycle times, low scrap rates, and stable performance across long-term serial manufacturing programs.

Why Choose MotMould as Your Injection Molding Partner

- Integrated mold design, tooling production, and injection molding capabilities

- Manufacturing-oriented engineering aligned with industrial production constraints

- Experience supporting OEM, ODM, and contract manufacturing programs

- Focus on tooling durability, process stability, and long-term production performance

- Scalable injection molding solutions for complex industrial applications

Contact Our Injection Molding Team

Contact our plastic injection molding team to discuss your manufacturing requirements and evaluate how MotMould can support your injection molding and serial production objectives.

Why Choose MotMould?

Mould is an engineering-driven industrial partner combining hands-on manufacturing experience with consulting expertise. We deliver production-ready solutions aligned with real industrial requirements, scalability, and long-term performance.

Hajdu Zsolt

CNC Solutions & Manufacturing Consultant

Nándor Motruk

Industrial Digital Manufacturing Consultant

Get in Touch with MotMould

Would you like to discuss your technical requirements or manufacturing challenges? Our industrial consultants are ready to evaluate production-ready solutions tailored to your business.