Industrial Automation & Robotics Services

MotMould delivers industrial automation and robotics services for manufacturing-driven companies, OEMs, and system integrators seeking reliable, scalable, and production-oriented automation solutions. We support automation projects from early concept and system design through integration, commissioning, and long-term operational support.

Our approach combines mechanical engineering, control systems, robotics integration, and manufacturing expertise to deliver automation solutions aligned with real production constraints, process stability, and long-term performance requirements.

Discuss your industrial automation or robotics project with our team.

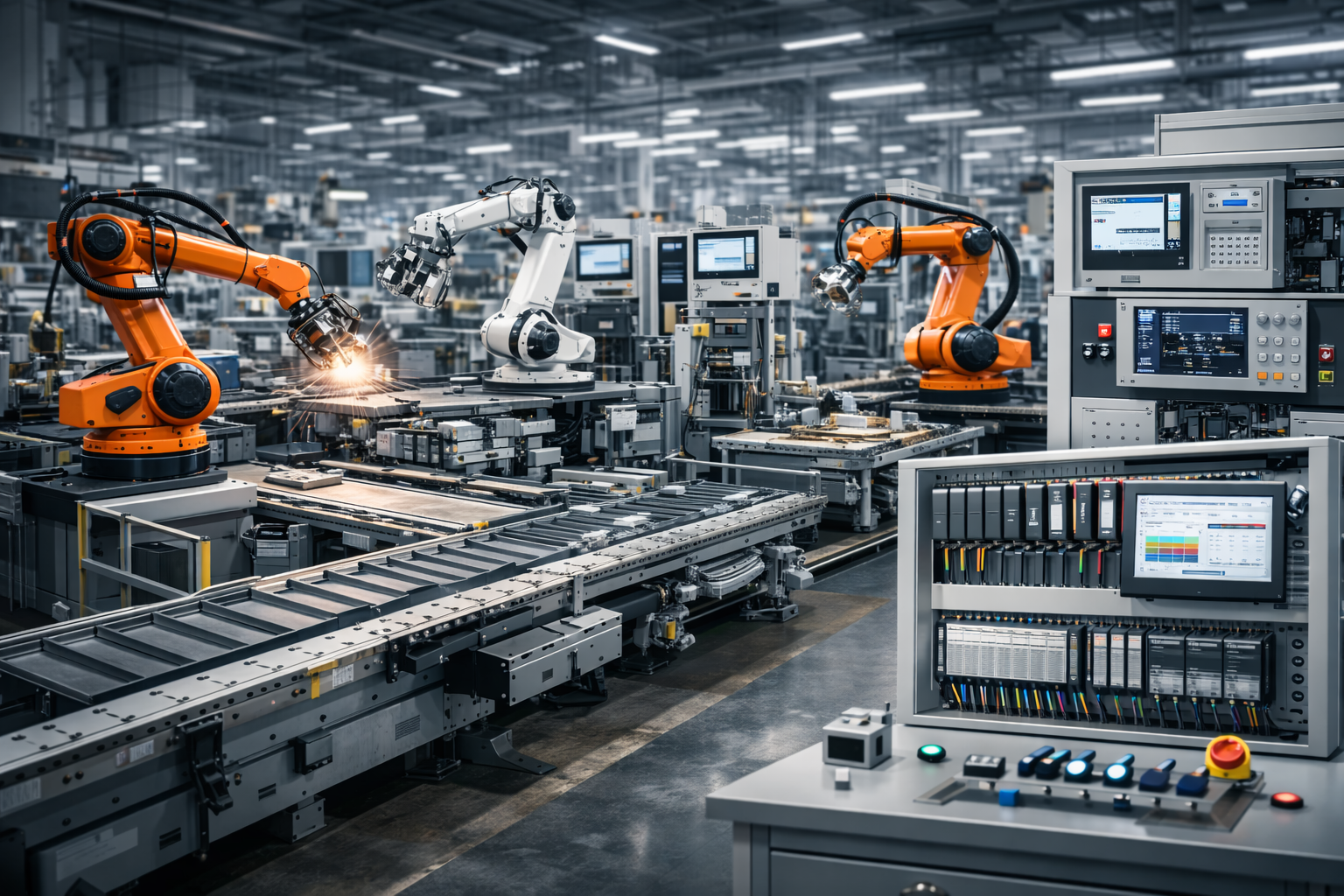

Integrated Industrial Automation & Robotics Capabilities

Our industrial automation and robotics services are structured to support productivity improvement, process reliability, and scalable manufacturing operations. We design and integrate automation systems that align with existing production infrastructure while enabling future expansion and optimization.

Automation System Design & Integration

We provide automation system design and integration services focused on efficient, reliable, and maintainable production systems. Our work includes system architecture definition, equipment selection, interface coordination, and full integration into existing manufacturing environments.

Automation solutions are engineered to ensure stable operation, repeatable cycle times, and seamless interaction between machines, robots, and control systems.

Robotics Integration & Programming

We deliver industrial robotics integration and programming services for robotic cells, handling systems, and automated workstations. Our capabilities include robot selection, cell layout design, offline and online programming, and optimization of robotic motion and cycle times.

Robotic systems are integrated with safety, vision, and control systems to ensure reliable and compliant operation.

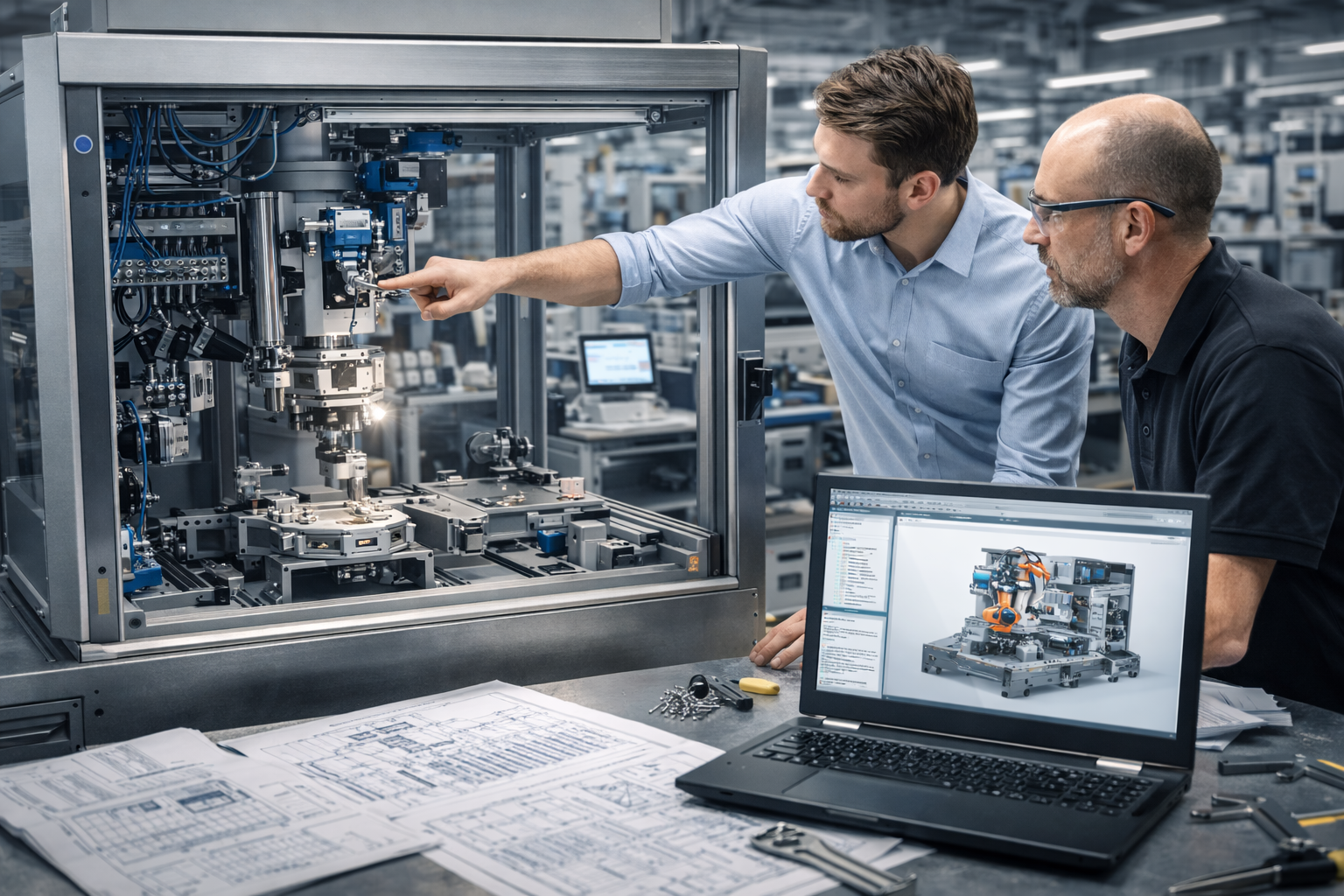

Custom Machine Design & Build

MotMould designs and delivers custom automated machines and special-purpose equipment tailored to specific manufacturing processes. These systems are developed to meet unique production requirements where standard automation solutions are insufficient.

Custom machines are engineered with a strong focus on reliability, serviceability, and long-term production performance.

Need a custom automation or robotic solution?

Let’s evaluate your production requirements and system constraints together.

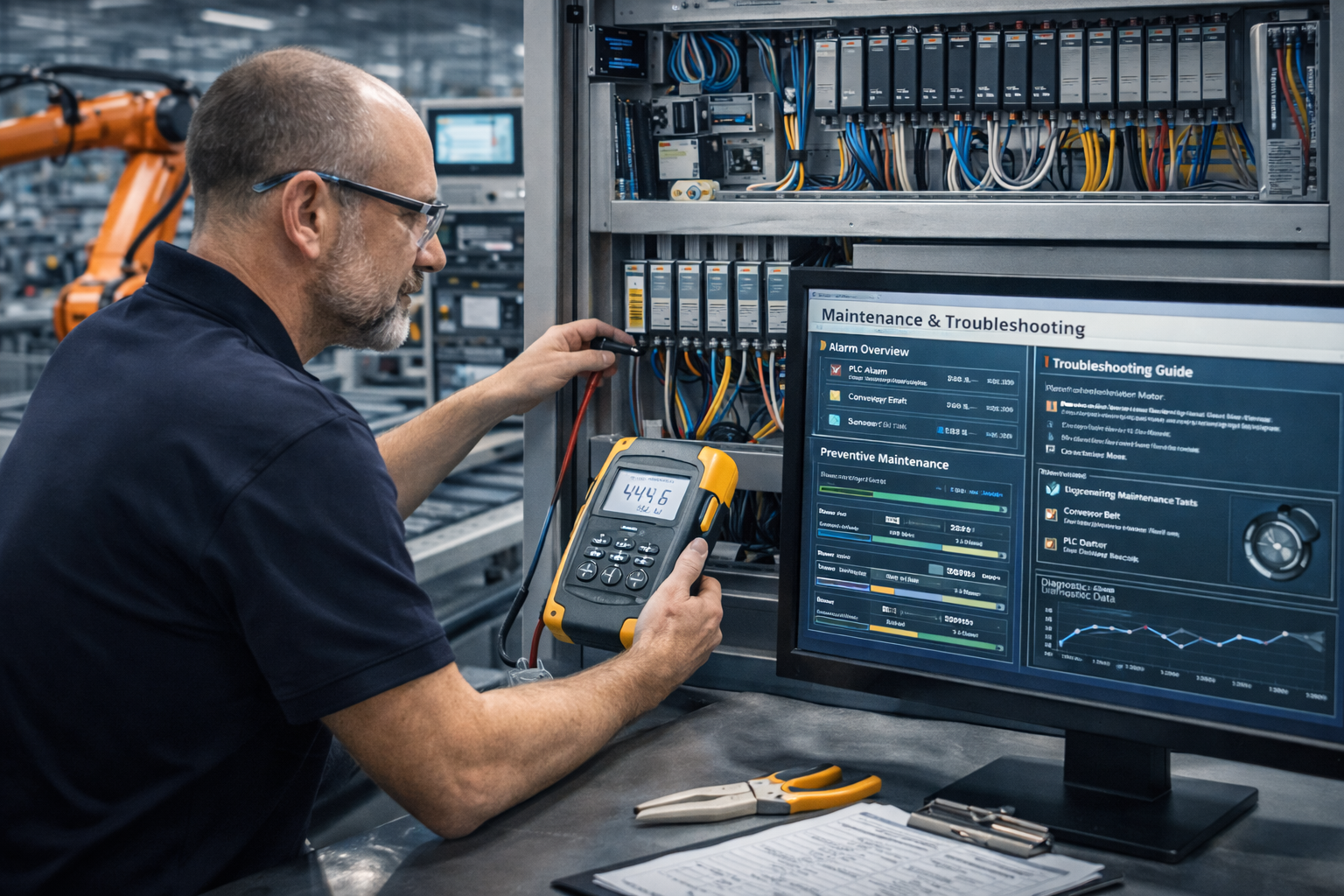

PLC Programming & Industrial Control Systems

We provide PLC programming and industrial control system development for automated manufacturing environments. Our services include control logic development, HMI design, system diagnostics, and commissioning support.

Control systems are designed for operational transparency, fault detection, and ease of maintenance, supporting stable and efficient production.

Factory Process Optimization & Cycle Time Reduction

We support factory process optimization initiatives aimed at improving throughput, reducing cycle times, and enhancing overall equipment effectiveness. Our engineering-driven approach identifies bottlenecks, inefficiencies, and automation opportunities within existing production systems.

Optimization efforts are validated through data-driven analysis and real production testing.

Conveyor Systems & Material Handling Automation

Our material handling and conveyor automation services support efficient part flow between manufacturing processes. We design and integrate conveyor systems aligned with production layouts, takt times, and handling requirements.

Material handling automation improves process stability, reduces manual intervention, and supports consistent production flow.

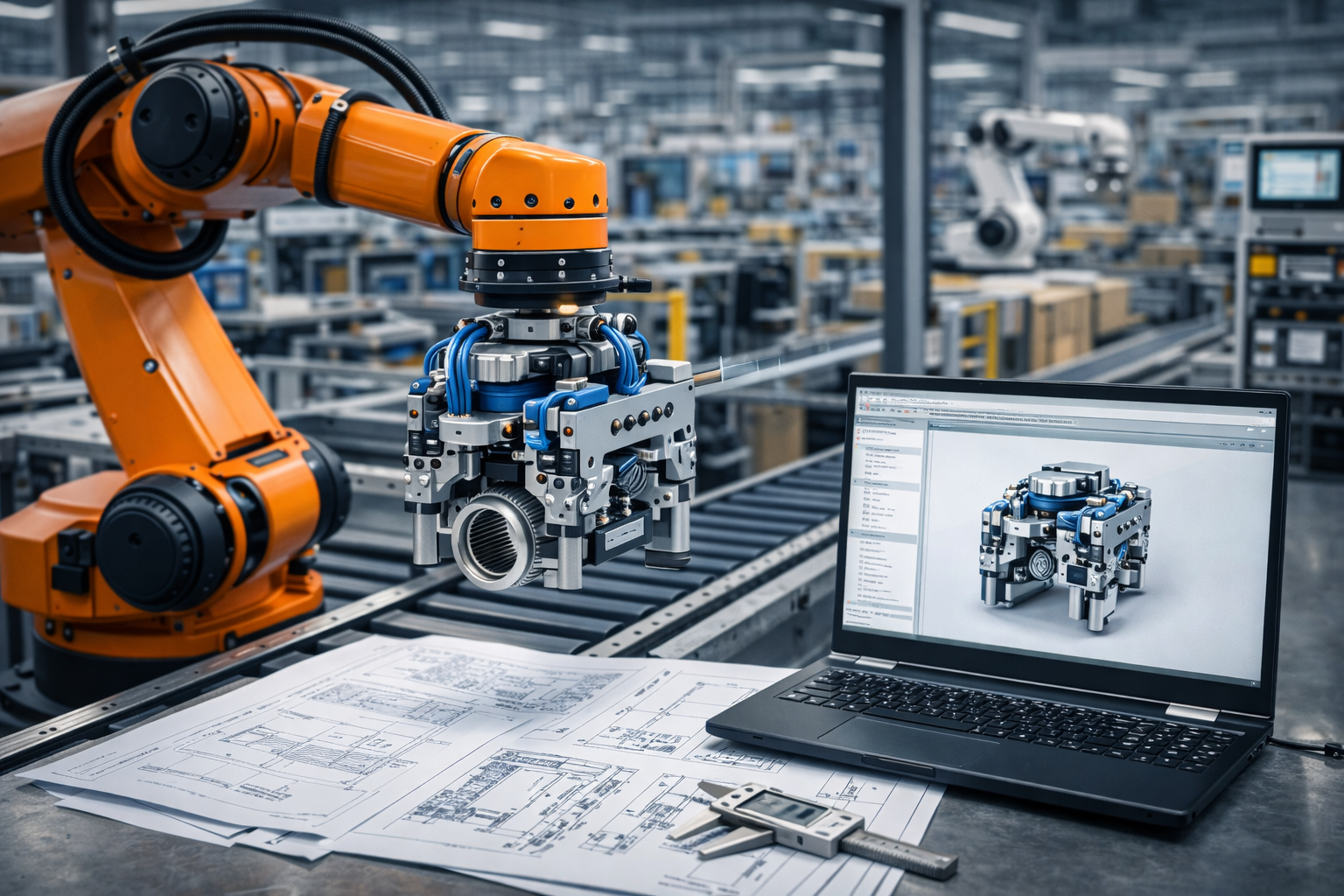

End-of-Arm Tooling (EOAT) Design & Integration

We design and integrate end-of-arm tooling for robotic applications, including grippers, fixtures, and specialized handling devices. EOAT solutions are engineered to ensure reliable part handling, precise positioning, and compatibility with robotic motion and process requirements.

EOAT design is closely aligned with part geometry, material properties, and cycle time objectives.

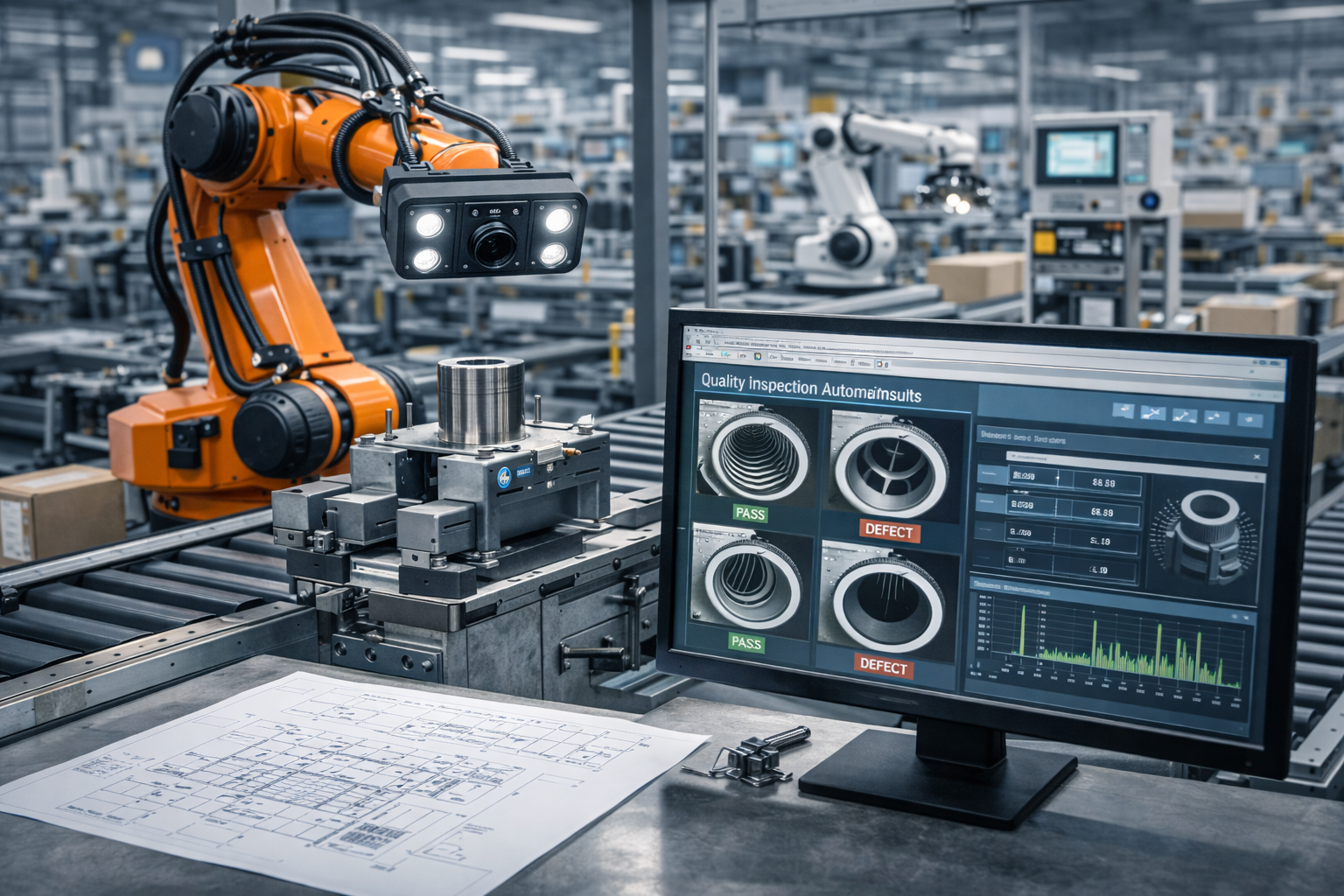

Vision Systems & Quality Inspection Automation

We integrate industrial vision systems for automated inspection, guidance, and quality control. Vision-based solutions support part presence detection, dimensional verification, orientation control, and process monitoring.

Vision systems are integrated into robotic and automation workflows to enhance process reliability and reduce manual inspection.

Safety Systems & Industrial Compliance

We implement industrial safety systems aligned with applicable standards and regulatory requirements. Safety integration includes risk assessment, safety PLCs, guarding, light curtains, and emergency stop systems.

Safety solutions are designed to protect operators while maintaining production efficiency and system availability.

Maintenance, Troubleshooting & Lifecycle Support

We provide maintenance, troubleshooting, and lifecycle support services for automation and robotic systems. Our support ensures long-term system reliability, performance optimization, and rapid issue resolution.

Lifecycle support helps maximize return on automation investments and ensures stable operation throughout system lifetime.

Industries We Support

- Industrial Manufacturing & Automation

- Automotive & Mobility Systems

- OEM Production & Assembly Lines

- Energy & Heavy Industry

- Machinery & Equipment Manufacturing

- Industrial Product Development

Why Choose MotMould for Industrial Automation & Robotics

- Integrated mechanical, electrical, and automation engineering expertise

- Production-oriented automation solutions aligned with real factory conditions

- Experience delivering custom machines and robotic systems

- Focus on reliability, maintainability, and long-term system performance

- Scalable automation solutions for complex industrial environments

Contact Our Automation & Robotics Team

Contact our industrial automation and robotics team to discuss your automation requirements and evaluate how MotMould can support your manufacturing and production optimization objectives.

Why Choose MotMould?

Mould is an engineering-driven industrial partner combining hands-on manufacturing experience with consulting expertise. We deliver production-ready solutions aligned with real industrial requirements, scalability, and long-term performance.

Hajdu Zsolt

CNC Solutions & Manufacturing Consultant

Nándor Motruk

Industrial Digital Manufacturing Consultant

Get in Touch with MotMould

Would you like to discuss your technical requirements or manufacturing challenges? Our industrial consultants are ready to evaluate production-ready solutions tailored to your business.