Industrial 3D Printers – Sales & Expert Consulting

MotMould provides industrial 3D printer sales and expert consulting services for manufacturing companies, OEMs, and engineering teams seeking reliable additive manufacturing solutions. We support customers throughout the entire decision-making and implementation process, ensuring that the selected 3D printing technology aligns with production goals, material requirements, and long-term operational needs.

Our approach combines in-depth technical expertise, application-driven consulting, and real manufacturing experience. From printer selection and workflow optimization to installation, training, and lifecycle support, we help organizations successfully integrate industrial 3D printing into existing manufacturing environments.

Discuss your industrial 3D printer requirements with our experts.

Industrial 3D Printer Sales & Consulting Capabilities

Our industrial 3D printer consulting and sales services are structured to reduce investment risk and ensure successful long-term adoption of additive manufacturing technologies. We focus on technology suitability, application feasibility, and production readiness rather than product-driven sales.

Professional Consultation for 3D Printer Selection

We provide expert consultation to help customers select the most suitable industrial 3D printer based on application requirements, production volumes, material performance, accuracy needs, and budget constraints. Our recommendations are technology-agnostic and aligned with real manufacturing use cases.

Industrial 3D Printers for Professional Manufacturing

We supply industrial-grade 3D printers designed for professional and production environments. These systems deliver reliability, repeatability, and consistent part quality suitable for prototyping, functional testing, tooling support, and low-volume production.

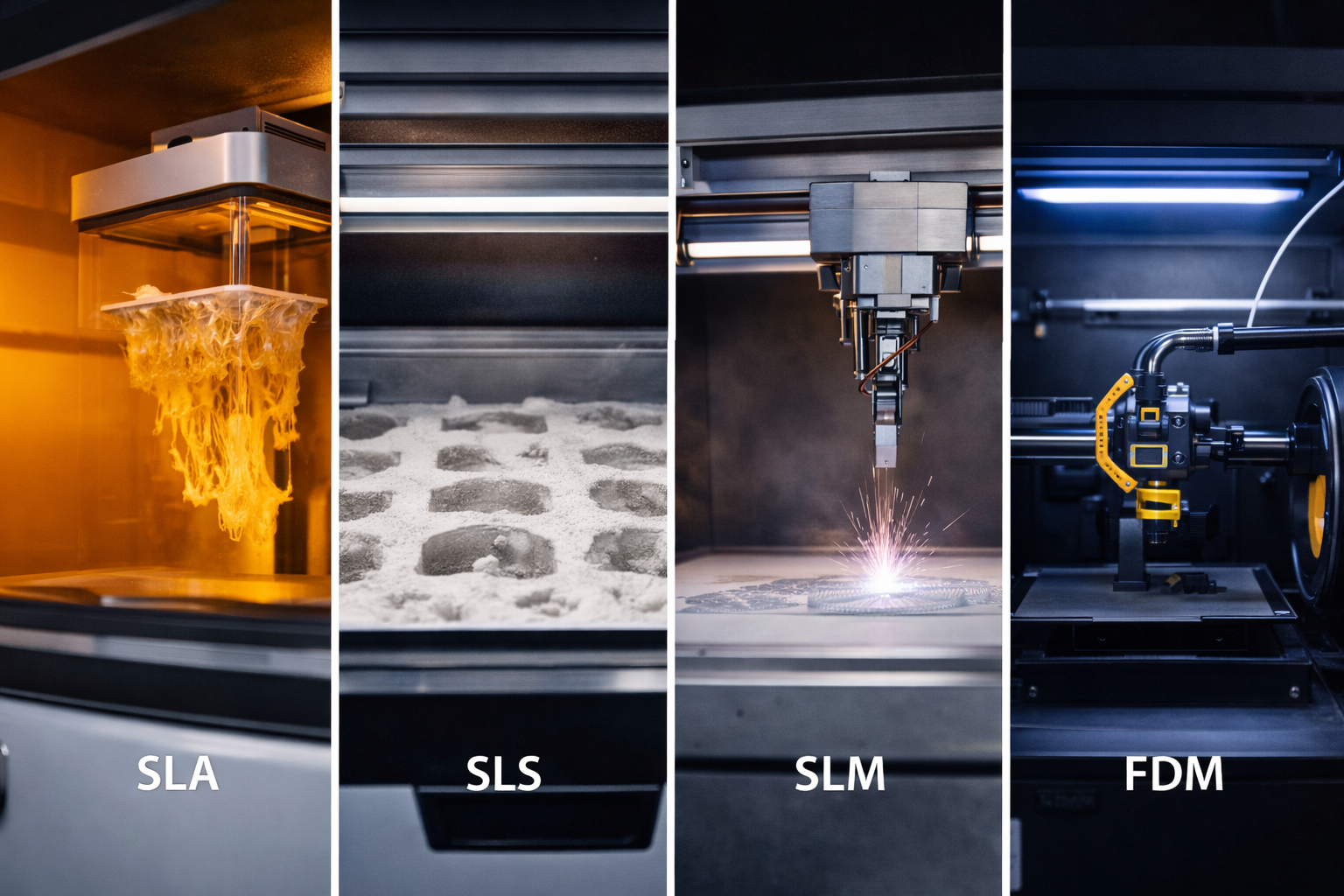

Technology Categories: SLA, SLS, SLM & FDM Printers

Our portfolio covers all major industrial additive manufacturing technologies, including SLA, SLS, SLM, and FDM. This allows us to recommend the optimal technology based on part geometry, mechanical requirements, surface quality, and intended production use.

Material Compatibility & Application Guidance

We advise on material compatibility and selection, ensuring that selected polymers, resins, composites, or metal alloys meet mechanical, thermal, chemical, and functional requirements. Material recommendations are aligned with both part performance and downstream manufacturing processes.

Installation, Calibration & Operator Training

We support industrial 3D printer installation, system calibration, and operator training to ensure correct setup, safe operation, and optimal performance from day one. Training focuses on practical operation, process stability, and repeatable production results.

Need help selecting and implementing the right industrial 3D printing system?

Let’s evaluate your application requirements and production objectives together.

Workflow Optimization for Additive Manufacturing

We help optimize additive manufacturing workflows, including data preparation, build strategies, post-processing, and integration with quality control processes. Workflow optimization improves part consistency, reduces rework, and increases overall production efficiency.

Maintenance, Service & Technical Support

We provide ongoing maintenance, service, and technical support to ensure long-term system reliability and minimize downtime. Our support services help protect investment value and maintain stable additive manufacturing operations.

Total Cost of Ownership (TCO) & ROI Advisory

We assist customers in evaluating total cost of ownership and return on investment, enabling informed purchasing decisions based on production efficiency, operational costs, and long-term business value rather than initial system price alone.

Integration With Existing Manufacturing Processes

We support seamless integration of industrial 3D printers into existing manufacturing, tooling, inspection, and assembly workflows. This ensures compatibility with current production systems and enables hybrid manufacturing strategies combining additive and conventional processes.

Why Choose MotMould for Industrial 3D Printer Consulting & Sales

- Technology-agnostic consulting focused on real manufacturing needs

- Industrial-grade 3D printers for professional and production environments

- Strong expertise across SLA, SLS, SLM, and FDM technologies

- End-to-end support from selection to installation and lifecycle operation

- Practical experience integrating additive manufacturing into production workflows

Contact Our Industrial 3D Printer Consulting Team

Contact our industrial 3D printer consulting team to discuss your additive manufacturing requirements and evaluate the most suitable 3D printing solution for your production environment.

Why Choose MotMould?

Mould is an engineering-driven industrial partner combining hands-on manufacturing experience with consulting expertise. We deliver production-ready solutions aligned with real industrial requirements, scalability, and long-term performance.

Hajdu Zsolt

CNC Solutions & Manufacturing Consultant

Nándor Motruk

Industrial Digital Manufacturing Consultant

Get in Touch with MotMould

Would you like to discuss your technical requirements or manufacturing challenges? Our industrial consultants are ready to evaluate production-ready solutions tailored to your business.