CNC Machinery & Equipment – Sales, Training & Expert Consulting

MotMould provides CNC machinery and equipment sales, training, and expert consulting services for manufacturing companies, OEMs, and production-focused engineering teams. We support customers across the full CNC lifecycle — from machine selection and process definition to installation, operator training, and long-term production support.

Our approach combines manufacturing engineering expertise, practical CNC machining experience, and application-driven consulting. We help organizations implement CNC milling, turning, and production machining solutions that are aligned with real shop-floor requirements, productivity targets, and quality standards.

Discuss your CNC machinery or machining requirements with our experts.

CNC Machinery Sales, Training & Consulting Capabilities

Our CNC services are structured to support efficient production machining, process reliability, and scalable manufacturing operations. We focus on correct machine selection, operator competence, and optimized workflows to ensure stable and repeatable production results.

Consulting for CNC Machine Selection

We provide expert consulting to support CNC machine selection based on part geometry, materials, tolerances, production volumes, and manufacturing strategy. Our recommendations consider technical capability, footprint, automation potential, and total cost of ownership.

Industrial CNC Machinery for Manufacturing

We supply industrial CNC machinery designed for professional manufacturing environments. These systems support high-precision milling, turning, and production machining with a strong focus on reliability, rigidity, and long-term performance.

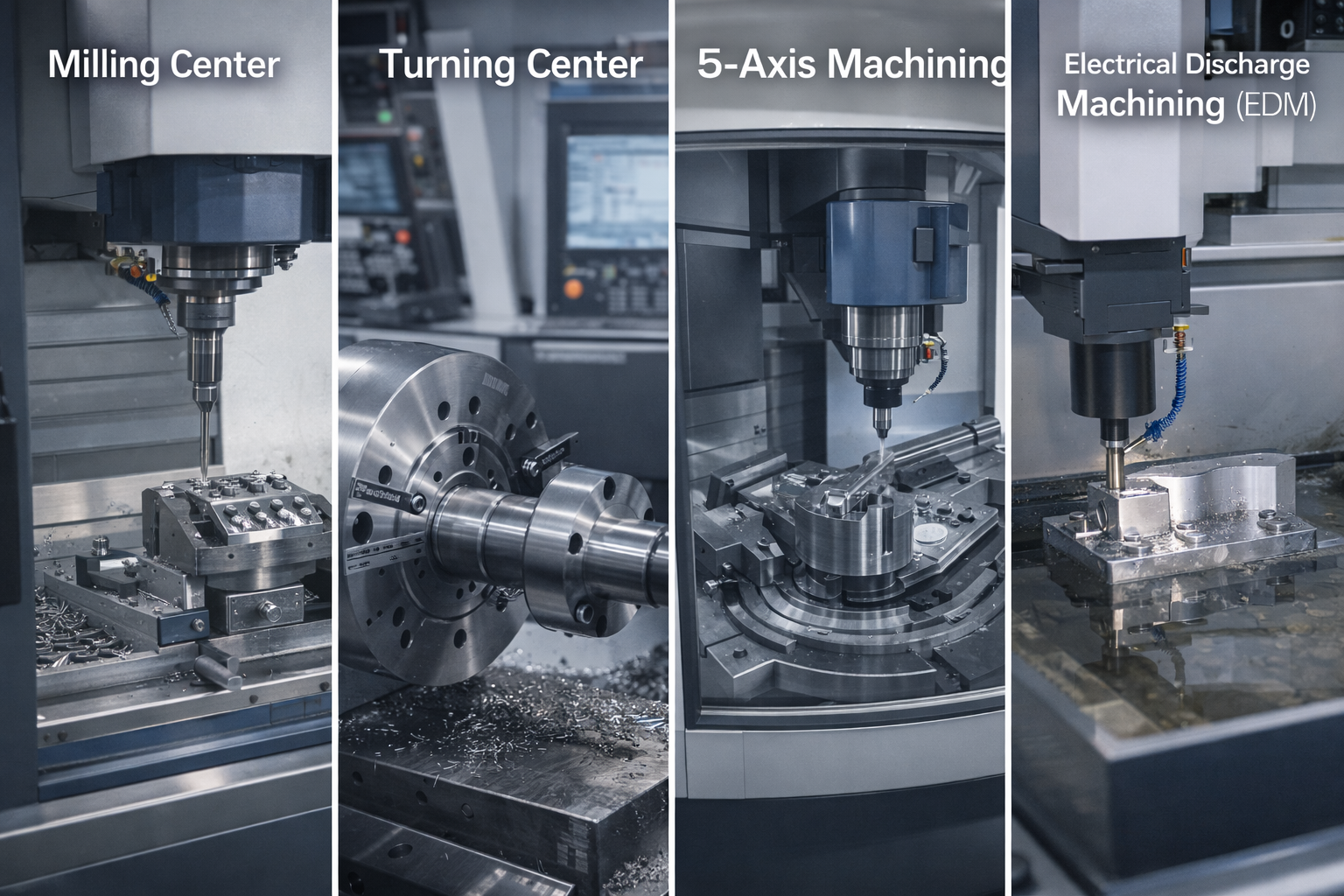

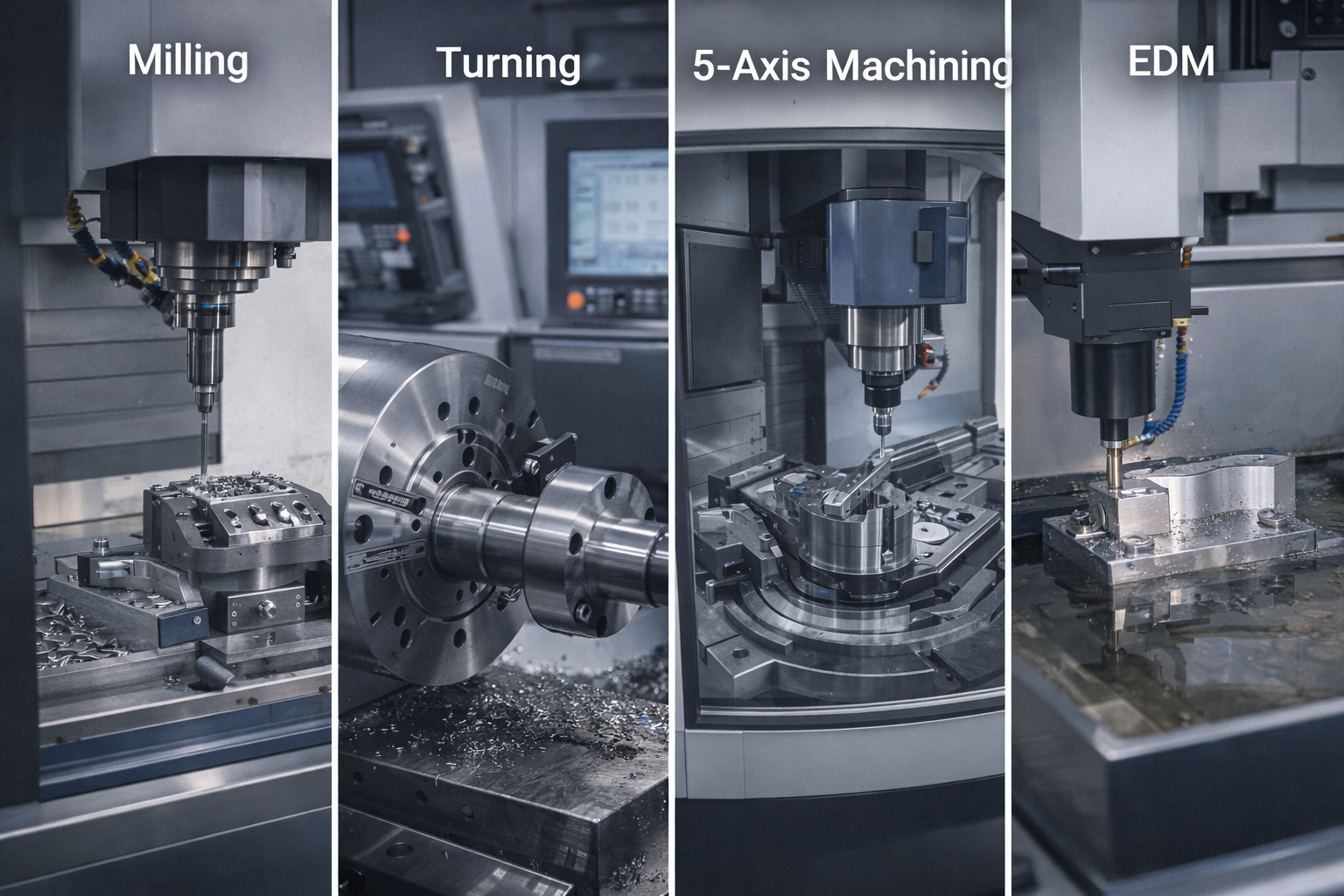

CNC Technology Categories: Milling, Turning, 5-Axis & EDM

Our CNC portfolio and consulting expertise cover all major CNC machining technologies, including milling centers, turning centers, 5-axis machining systems, and EDM solutions. This enables optimal technology selection for complex geometries, tight tolerances, and demanding materials.

CNC Installation, Setup & Calibration Services

We support CNC machine installation, setup, and calibration to ensure correct alignment, accuracy, and safe operation. Proper commissioning is essential for achieving stable machining performance and meeting dimensional requirements from the first production runs.

CNC Operator Training & Skill Development

We provide CNC operator training and skill development programs focused on machine operation, process understanding, and best machining practices. Training improves productivity, reduces scrap, and supports consistent quality in daily production.

Need support selecting and implementing the right CNC machining solution?

Let’s evaluate your production requirements and machining processes together.

CNC Programming Support (G-Code & CAM Integration)

We offer CNC programming support, including G-code development and CAM software integration. Our services ensure efficient toolpaths, optimized cutting strategies, and compatibility between CAD/CAM systems and machine controllers.

Workflow Optimization for CNC Manufacturing

We help optimize CNC manufacturing workflows by analyzing setup strategies, tooling, cycle times, and material flow. Workflow optimization improves throughput, reduces changeover time, and increases overall equipment effectiveness.

CNC Machine Maintenance & Troubleshooting

We provide maintenance and troubleshooting support to keep CNC machines operating reliably. Our services include diagnostics, process-related issue resolution, and guidance for preventive maintenance strategies.

Tooling, Fixturing & Workholding Solutions

We support tooling, fixturing, and workholding solution selection and design to ensure machining stability, repeatability, and dimensional accuracy. Proper workholding is critical for achieving consistent results in production machining.

CNC Machining Capabilities

Our CNC machining expertise supports both prototype and production manufacturing, including:

- CNC Milling for precision components

- CNC Turning for rotational parts

- Production machining for low- and medium-volume series

These capabilities enable flexible manufacturing support aligned with customer-specific production needs.

Why Choose MotMould for CNC Machinery & Consulting

- Integrated CNC machine sales, training, and consulting services

- Practical machining expertise aligned with real shop-floor conditions

- Support for milling, turning, 5-axis machining, and EDM technologies

- Focus on process stability, quality, and production efficiency

- Scalable CNC solutions for industrial manufacturing environments

Contact Our CNC Machinery & Consulting Team

Contact our CNC machinery and consulting team to discuss your machining requirements and evaluate the most suitable CNC solutions for your production environment.

Why Choose MotMould?

Mould is an engineering-driven industrial partner combining hands-on manufacturing experience with consulting expertise. We deliver production-ready solutions aligned with real industrial requirements, scalability, and long-term performance.

Hajdu Zsolt

CNC Solutions & Manufacturing Consultant

Nándor Motruk

Industrial Digital Manufacturing Consultant

Get in Touch with MotMould

Would you like to discuss your technical requirements or manufacturing challenges? Our industrial consultants are ready to evaluate production-ready solutions tailored to your business.