Industrial 3D Scanning & Reverse Engineering Services

Industrial 3D Scanning & Reverse Engineering Services

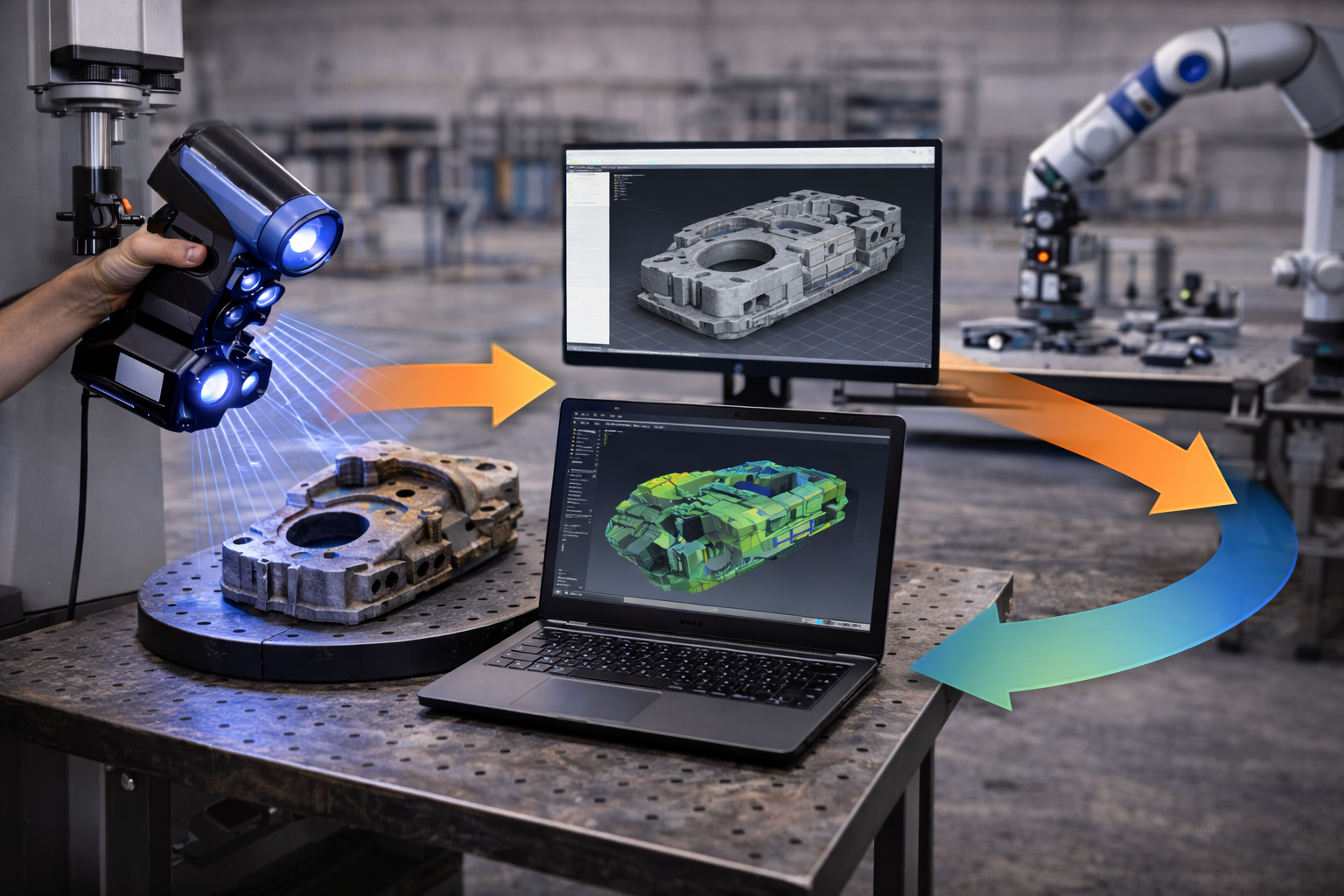

MotMould provides advanced industrial 3D scanning and reverse engineering services for manufacturing-driven companies, OEMs, and industrial system integrators requiring high-accuracy measurement and engineering-grade digital data. Our services enable precise digitization, inspection, and reconstruction of components, assemblies, and large-scale industrial assets.

We support the complete digital engineering lifecycle — from high-resolution data acquisition and on-site scanning to CAD reconstruction, dimensional analysis, and production validation. Our approach combines metrology-grade accuracy with practical manufacturing expertise, ensuring scanned data can be reliably used for design, tooling, quality control, and industrial decision-making.

Discuss your industrial 3D scanning or reverse engineering project with our team.

Integrated Industrial 3D Scanning & Reverse Engineering Capabilities

Our industrial 3D scanning and reverse engineering services are structured to support product development, tooling verification, quality assurance, facility digitization, and long-term asset management. We bridge physical assets and digital engineering environments by delivering accurate, traceable, and usable data.

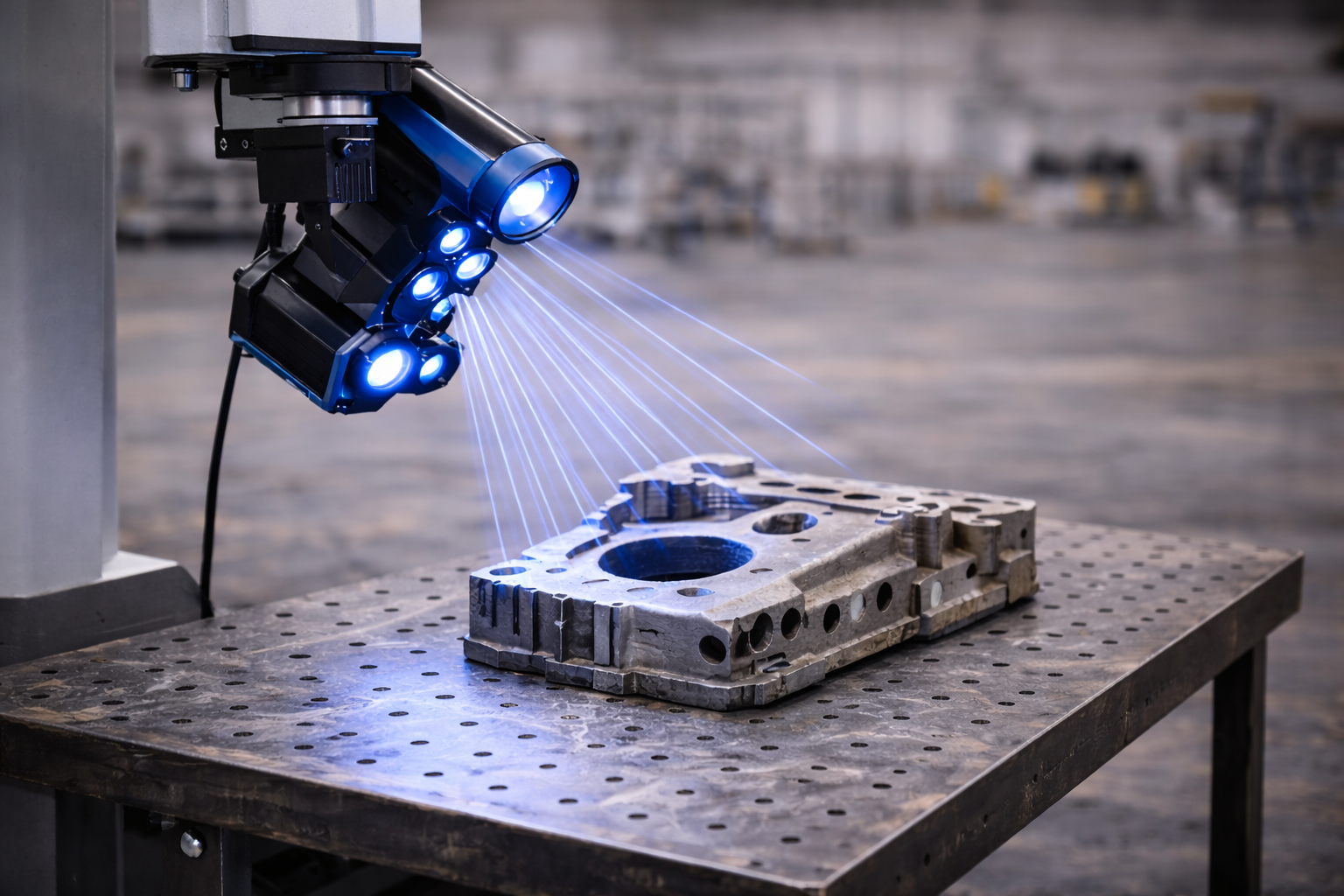

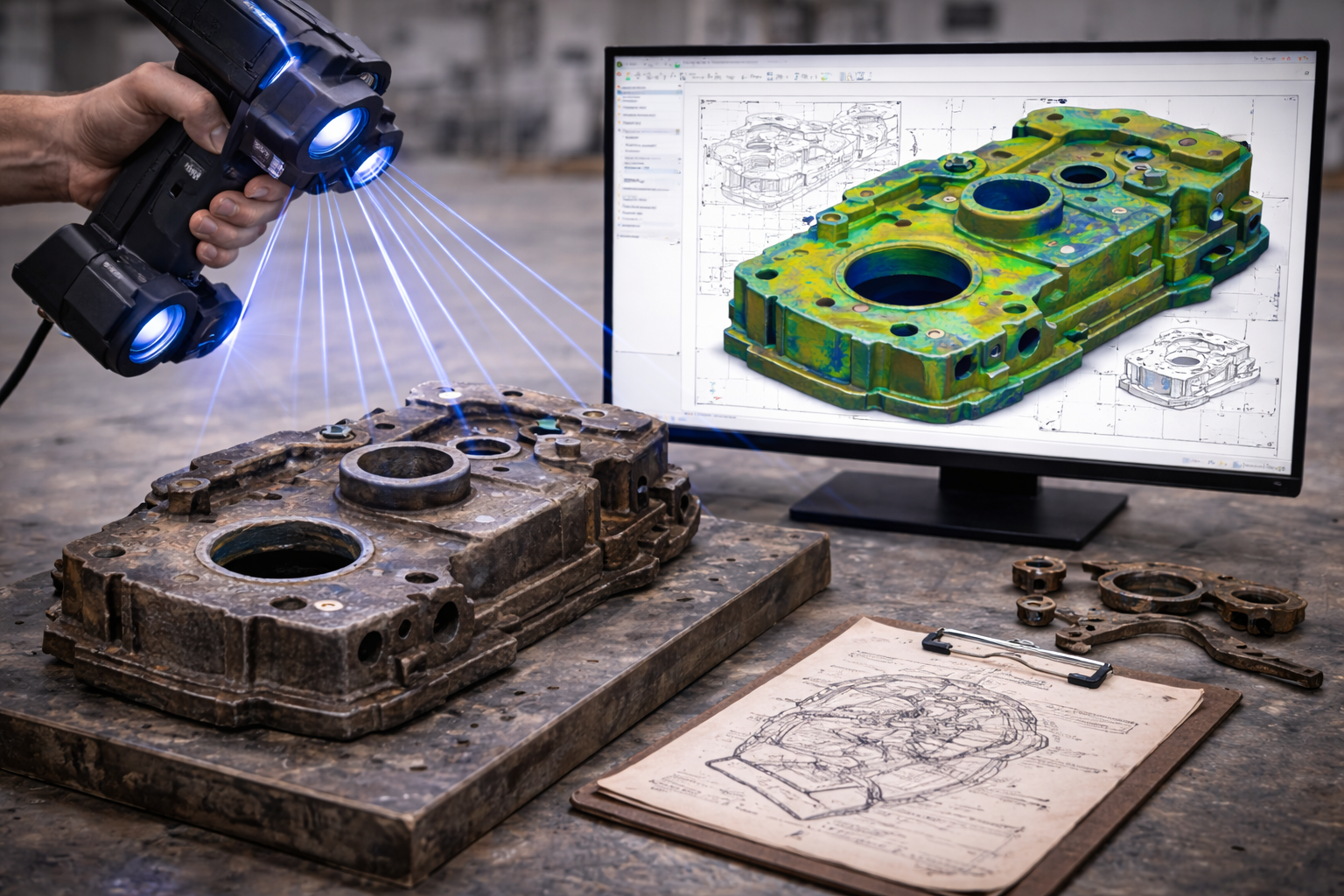

High-Accuracy Industrial 3D Scanning

We deliver high-accuracy industrial 3D scanning services for components and assemblies requiring precise geometric and surface data capture. Our scanning workflows achieve engineering- and metrology-grade accuracy suitable for dimensional verification, CAD reconstruction, tolerance evaluation, and manufacturing validation.

High-resolution scanning captures complex freeform surfaces, fine geometric details, and critical functional features, ensuring reliable data for downstream engineering, quality, and tooling applications.

LiDAR Scanning for Large Objects & Environments

Our LiDAR scanning services support the digitization of large objects, assemblies, and industrial environments where conventional measurement methods are inefficient or impractical. LiDAR technology enables rapid acquisition of large-scale spatial data, supporting applications such as plant layout documentation, large tooling inspection, structural assessment, and facility modernization.

The resulting point cloud data can be integrated into CAD, BIM, or digital twin environments to support engineering analysis, planning, and asset management.

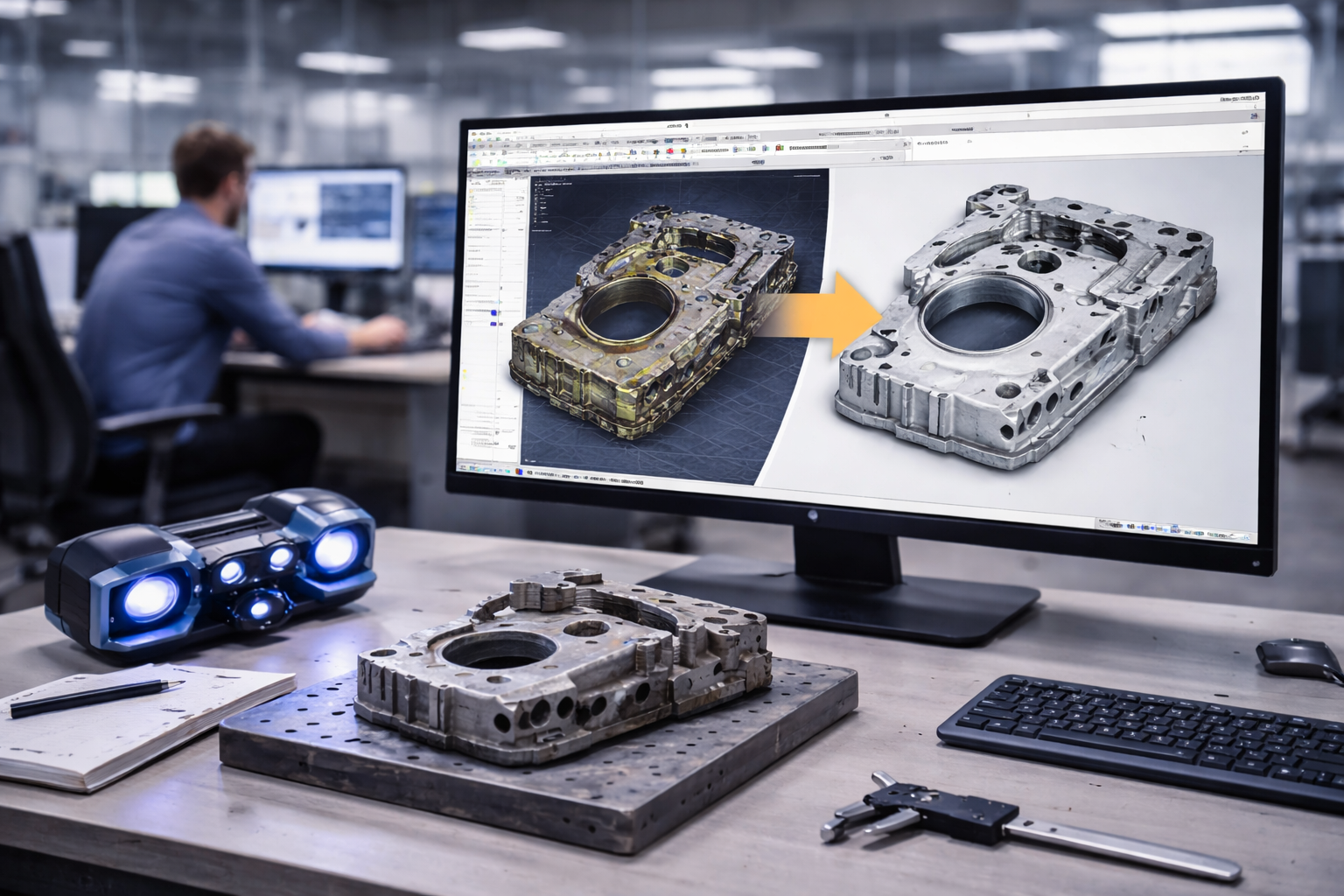

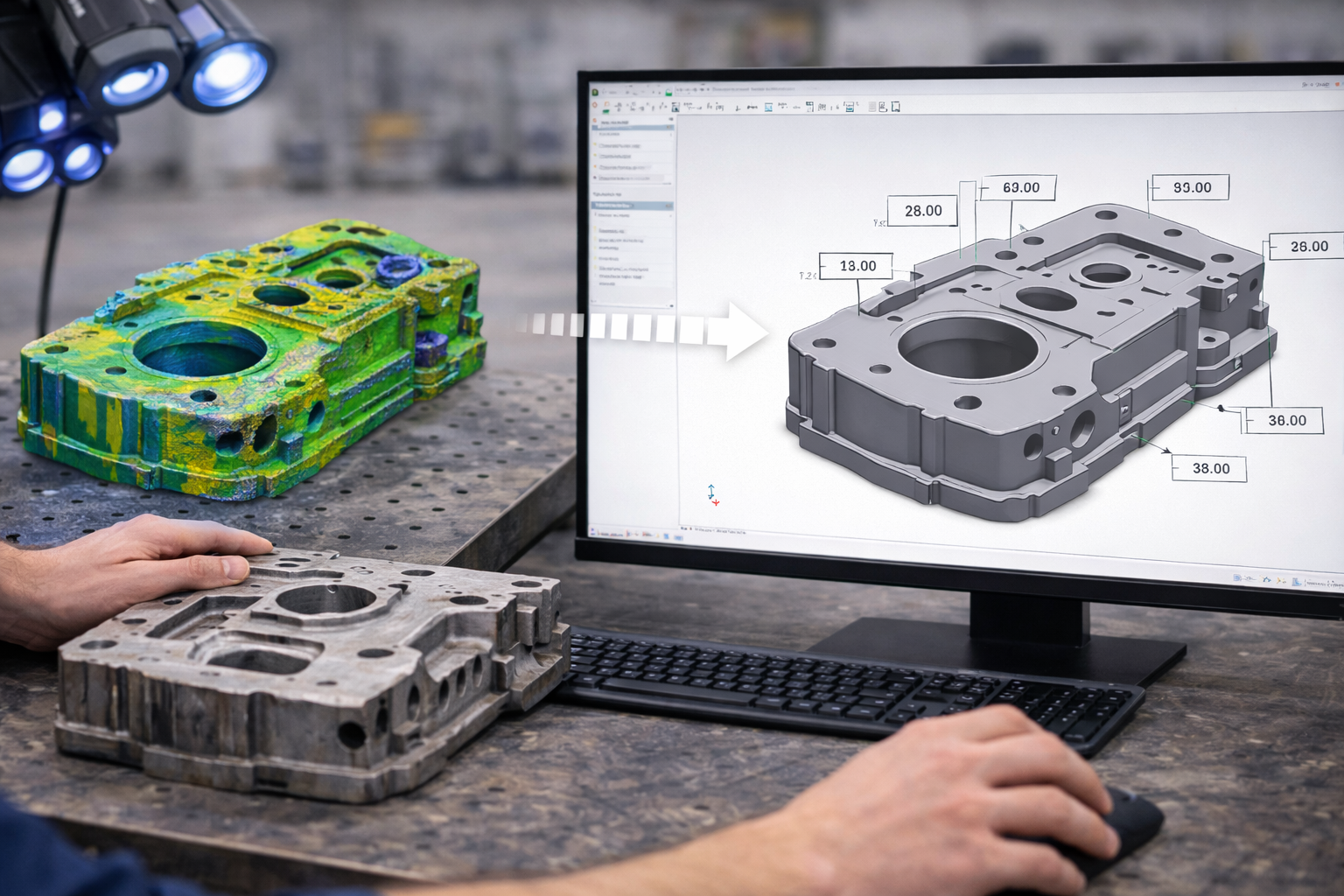

Reverse Engineering & CAD Reconstruction

We provide advanced reverse engineering and CAD reconstruction services that transform raw scan data into fully parametric, editable CAD models. These models preserve functional intent, geometric accuracy, and manufacturability, enabling redesign, performance optimization, tooling development, and simulation.

Reverse engineering supports modernization of components and systems where original CAD data is unavailable, incomplete, or outdated.

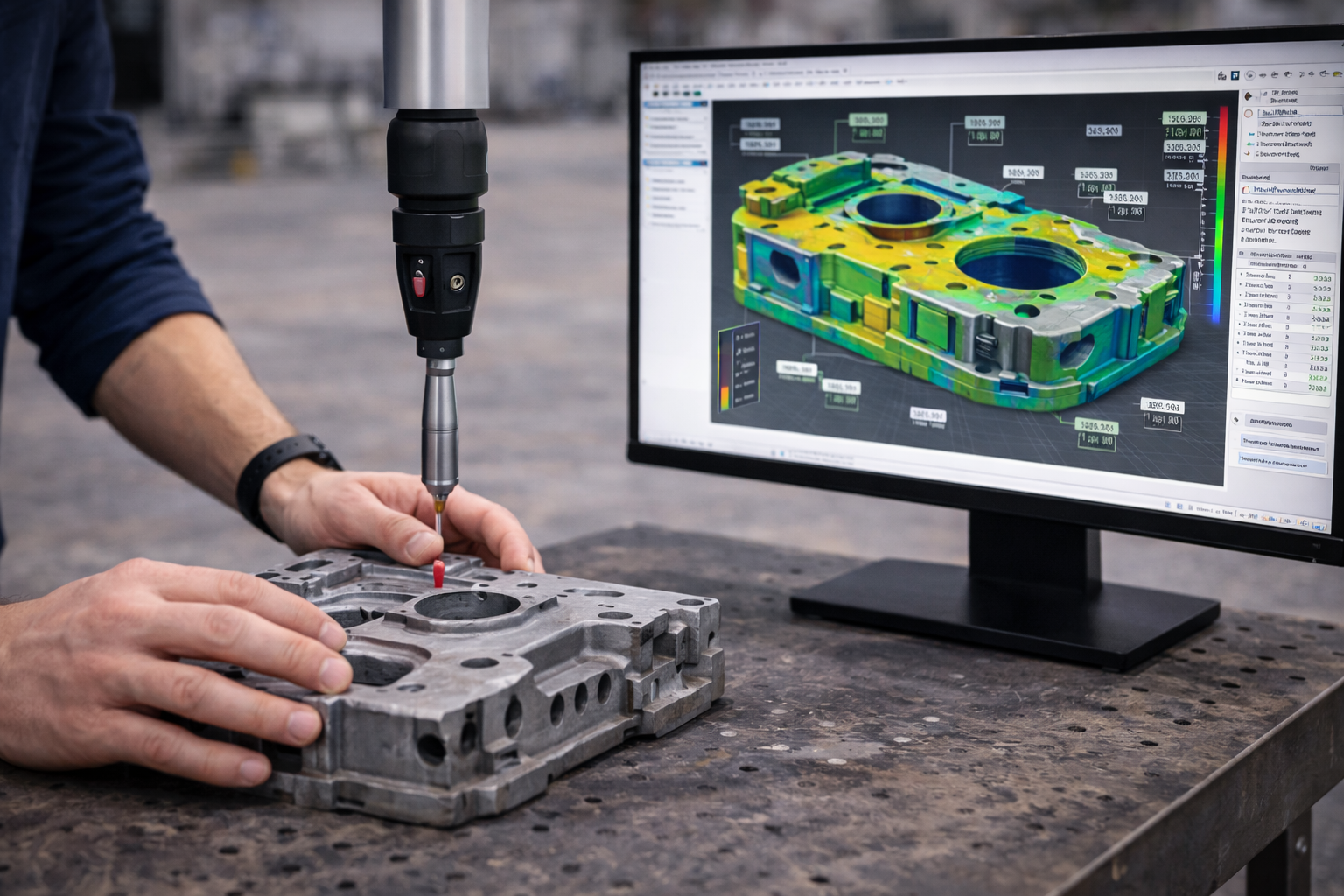

Dimensional Inspection & Quality Control

Our dimensional inspection and quality control services compare scanned data against nominal CAD models or technical drawings. This process identifies deviations, wear patterns, deformation, or assembly misalignment, supporting production validation, supplier control, and root cause analysis.

Inspection results deliver traceable, data-driven insight for manufacturing control and corrective action planning.

Scan-to-CAD Modeling

We offer scan-to-CAD modeling services that convert point cloud or mesh data into engineering-grade CAD geometry. Models are created with proper feature definition, parametric structure, and geometric continuity to ensure usability across downstream workflows.

Scan-to-CAD models support design modification, simulation, tooling engineering, and manufacturing preparation.

Legacy Part Digitization

Our legacy part digitization services enable the reproduction, refurbishment, or modernization of components where original CAD documentation no longer exists. This capability supports spare part production, equipment refurbishment, and long-term lifecycle management of industrial assets.

Digitized parts can be adapted to modern materials and manufacturing processes while maintaining functional compatibility.

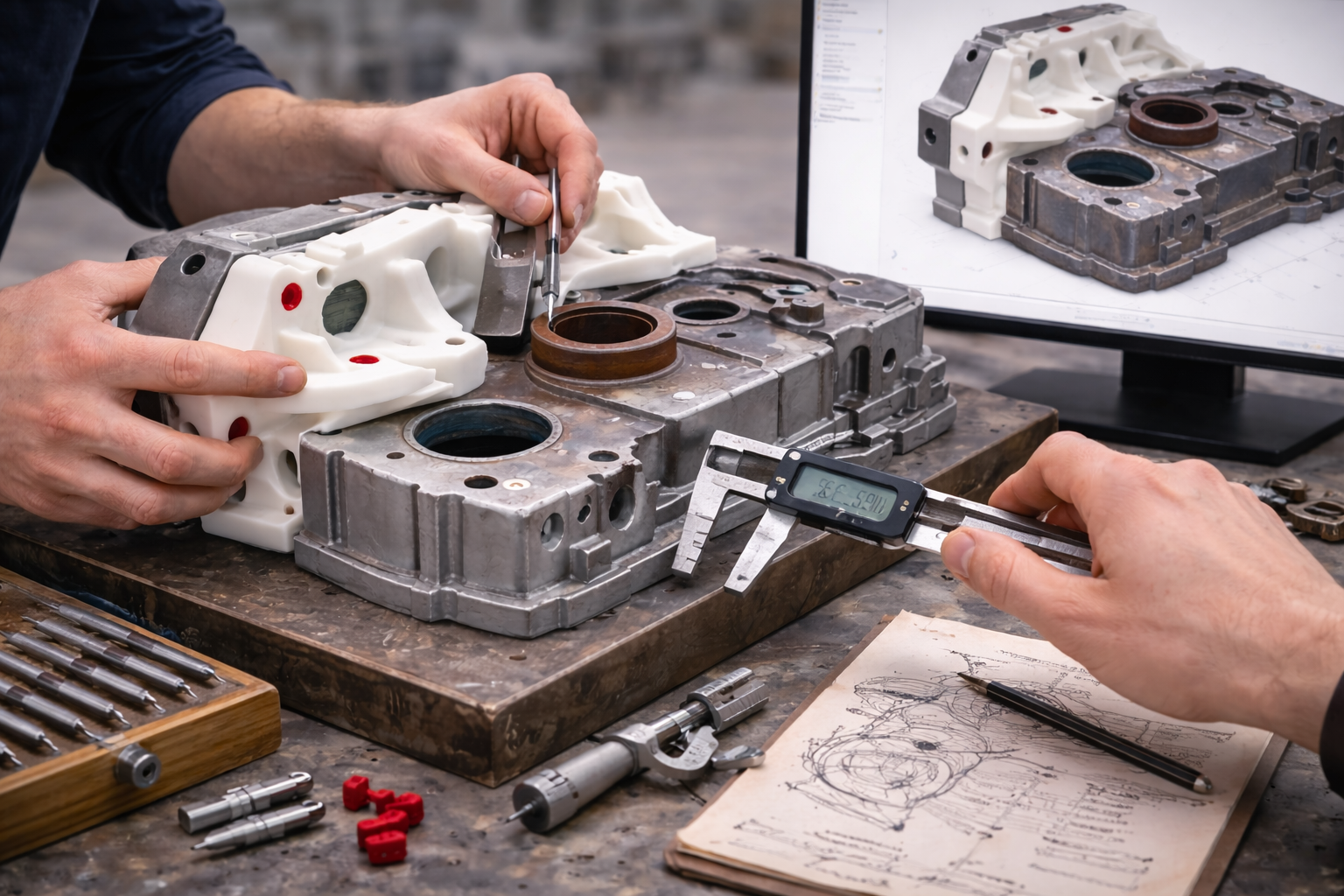

Prototype Verification & Fit Testing

We support prototype verification and fit testing by comparing scanned prototypes or assemblies against design intent. This validates form, fit, and functional alignment early in the development cycle.

Prototype verification reduces risk prior to tooling investment, assembly integration, or serial production.

On-Site 3D Scanning Services

Our on-site 3D scanning services enable direct data acquisition at customer facilities, minimizing downtime and logistical complexity. This approach is ideal for large equipment, fixed installations, tooling in production, or time-critical projects.

On-site scanning ensures accurate measurement while maintaining operational continuity.

Industries We Support

- Industrial Manufacturing & Automation

- Tooling, Molds & Production Equipment

- Automotive & Mobility Systems

- Energy, Power & Heavy Industry

- Aerospace & Large-Scale Assemblies

- OEM Product Development & Modernization

Why Choose MotMould for Industrial 3D Scanning & Reverse Engineering

Engineering- and metrology-grade accuracy suitable for manufacturing decisions Advanced scanning technologies for small components to large industrial environments Integrated scan-to-CAD, reverse engineering, and inspection expertise Strong focus on data usability in real production workflows Flexible on-site and off-site service delivery

Contact Our 3D Scanning & Reverse Engineering Team

Contact our industrial 3D scanning team to discuss your measurement, reverse engineering, or digitization requirements and evaluate how MotMould can support your engineering, quality, and manufacturing objectives.

Why Choose MotMould?

Mould is an engineering-driven industrial partner combining hands-on manufacturing experience with consulting expertise. We deliver production-ready solutions aligned with real industrial requirements, scalability, and long-term performance.

Hajdu Zsolt

CNC Solutions & Manufacturing Consultant

Nándor Motruk

Industrial Digital Manufacturing Consultant

Get in Touch with MotMould

Would you like to discuss your technical requirements or manufacturing challenges? Our industrial consultants are ready to evaluate production-ready solutions tailored to your business.